Choosing a cleaning hose with textile layer or steel layer?

Cleaning hoses are available in various designs. For example, you can choose between a hose with a textile layer or a hose with a steel layer. But what is the difference between these two designs and when do you opt for steel and when for textile?

The textile or steel layer is the layer between the outer wall and the inner wall of the cleaning hose. It is a woven layer – made from textile or steel – that determines the stiffness and service life of the hose. Many people think, incorrectly, that steel is a better choice than textile. Nothing could be further from the truth. Elpress recommends – where possible – opting for a cleaning hose with textile layer because this offers various advantages compared to a hose with steel layer. But sometimes, the only choice is steel.

Cleaning hose: easier to use

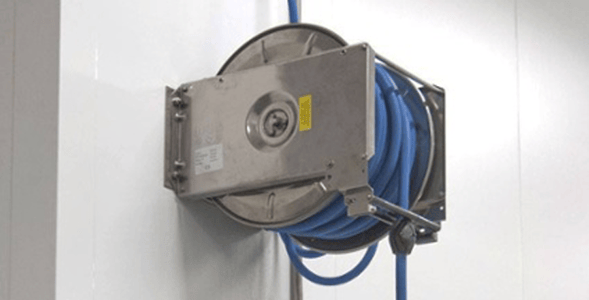

An HP cleaning hose from Elpress has two textile layers. A cleaning hose with a textile layer is more flexible than a hose with a steel layer. The latter is stiffer and more difficult to use. A hose with a textile layer is more flexible, more kink-resistant and also has a smoother outer wall. This makes the hose easier to move around. A hose with a textile layer is also lighter in weight, which naturally makes it easier to work with.

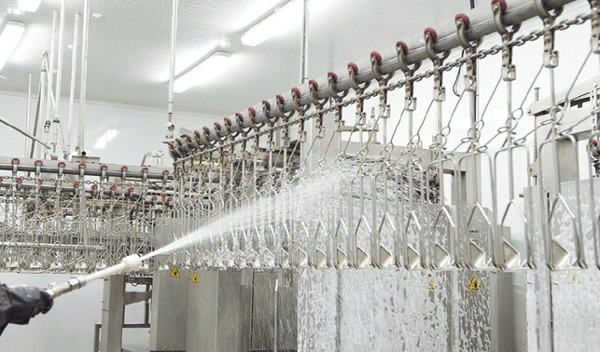

Textile layer cleaning hose: hygienic and sustainable

The smooth outer wall of the hose with a textile layer makes it much less susceptible to bacteria than a hose with a steel layer. A hose with a textile layer is also much more resistant to wear and thus has a longer service life. A hose with a steel layer has a weave in the outer wall – or a ‘winding’ – in which bacteria can accumulate more easily. When the hose has been in use for a long time and the outer wall has become damaged, the hygiene level clearly declines. The steel then breaks through and is exposed, moisture comes into play and causes oxidation. This not only causes a bacteriological risk but also shortens the service life of the hose. Moreover, the steel fibres can also come loose and employees can cut their hands on them.

The working pressure of a steel layer cleaning hose

A cleaning hose with a textile layer therefore seems to be the better option. But when can this type of hose not be used, and is a hose with a steel layer the better option? This has everything to do with the working pressure. Hoses with a textile layer can tolerate a working pressure of up to max. 200 bar. Above that, a hose with a steel layer is mandatory. The HP-Blue hoses from Elpress have a double steel layer and can tolerate a working pressure of up to 275 bar. In terms of safety, however, a maximum working pressure of 100 bar is recommended for the textile layer. This has to do with the high temperatures of the cleaning water and the press-in couplings of the hose, which can deform under high pressure in combination with high temperatures and ultimately come off.

More information about cleaning hoses for your company?

Would you like to know which cleaning hose is suitable for your company’s situation? Our specialists would be happy to help!

.png)