An industrial cleaning system: what precisely does it look like?

If you want to purchase an industrial cleaning system, you will obviously want to know precisely what this kind of installation looks like. In this blog, Elpress provides a clear description of the parts of such a system.

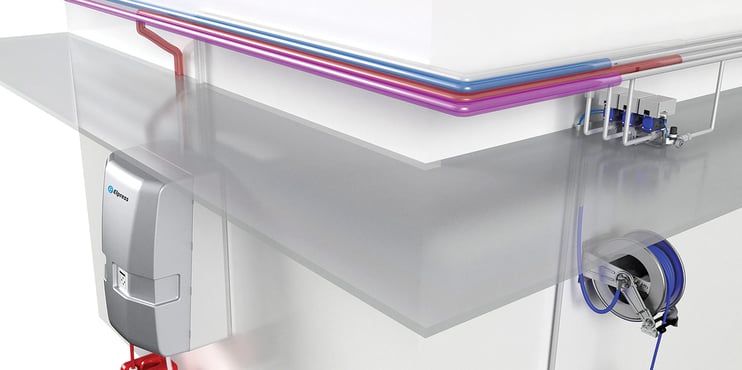

In brief, an industrial cleaning system consists of a booster unit, a network of pipes and often several satellites. A centralised system makes use of a foaming and disinfection unit and a central chemical storage facility. A decentralised system makes use of separate jerrycans at the satellites.

Cleaning system with a booster unit

There are various types of booster units available which take the water from the public mains and raise it to the desired pressure: low pressure (20 bar), medium pressure (maximum 44 bar) or high pressure (minimum 60 bar). The number of users that can use the system at the same time determines which pump is suitable for your business. One frequently used option is to place a stainless steel break tank in the installation. In this way, the installation has an approved non-return device.

Cleaning system with a foaming and disinfecting unit

Depending on the desired hygienic process within your business, you can choose foam cleaning only or both foam cleaning and disinfecting. A centralised cleaning system makes use of a foaming and disinfecting unit with a break tank. The dosing system ensures a constant dosing percentage and is frequency controlled. This ensures efficient cleaning and safer use of chemicals.

Cleaning system with a chemical storage system

In a centralised cleaning system, a central bulk store is used to store the chemicals. Depending on the type, this can store between 250 an 1,500 litres of detergent. The dosing pump of this storage system works on compressed air. In decentralised cleaning systems, collection trays and jerrycan trolleys are available for the safe placing and transporting of jerrycans.

Satellites

The pressurised water (including chemical in a centralised system) is transported to the satellites via a network of pipes. In a decentralised system, these stations are manually operated, while a centralised system can also be operated pneumatically. With each type of station, it is easy to choose the required cleaning activities: rinsing, foam cleaning or disinfecting. The quantity of air and the composition of the foam can also be controlled with the satellite.

Would you like more information about cleaning systems?

Would you like to know more about industrial cleaning? Then download the whitepaper ‘A total solution for industrial cleaning in the food sector’.

.png)